Focus on high-performance insulation solutions

Focus on high-performance insulation solutions

Process Boilers should be equipped for a wide range of requirements. They are supposed to withstand extremely high temperatures. However, they should also be able to tolerate significant temperature differences as the temperatures in various areas of the construction fluctuates greatly. In addition, the casing and pipes of boilers are usually exposed to constant vibrations caused by connected devices such as burners and blowers.

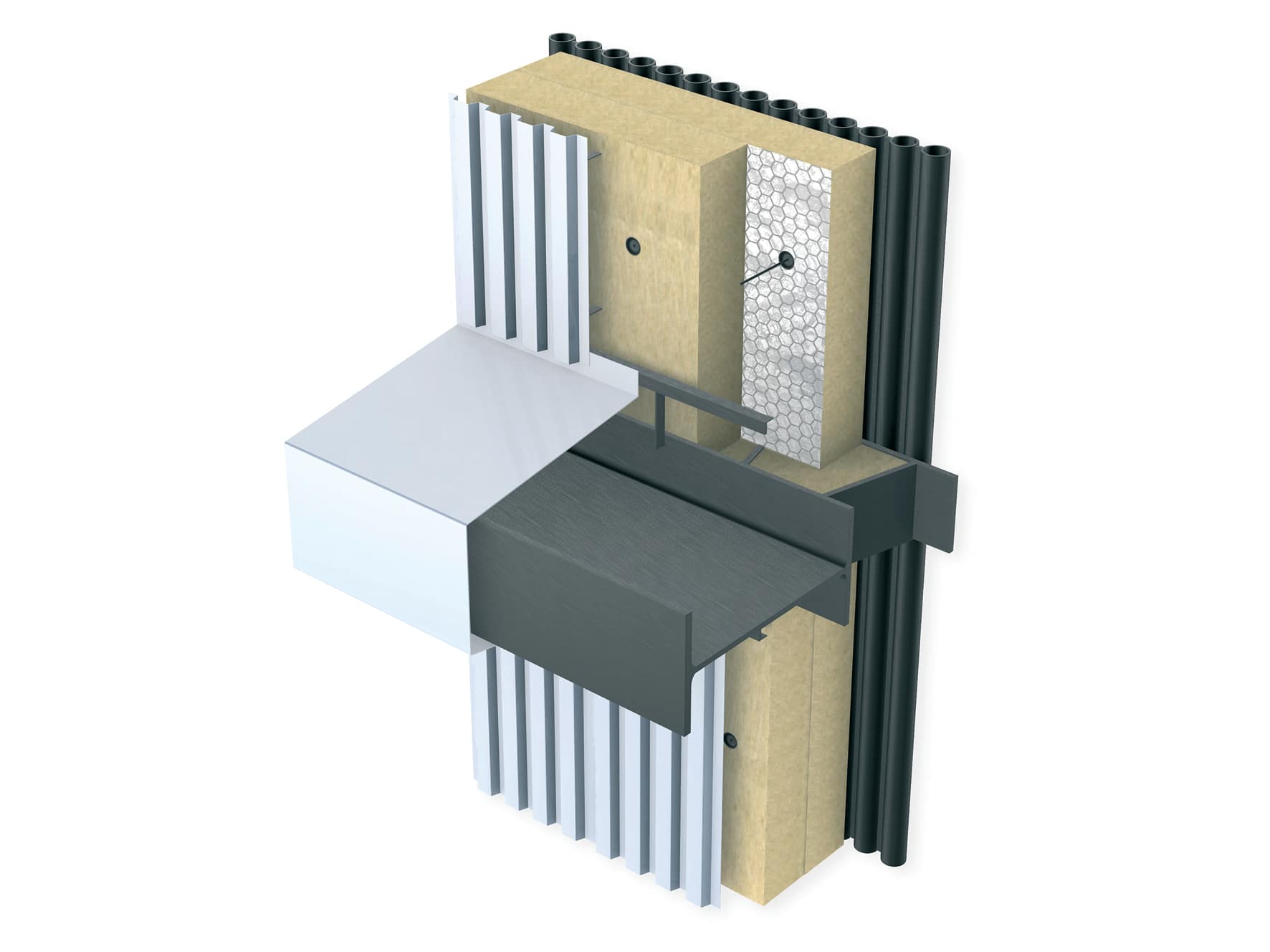

Proper insulation for power plant boilers is therefore essential to help minimize thermal loss and thermal bridges in the boiler as well as prevent the boiler room from overheating. We recommend a boiler insulation solution consisting of two to four layers to help control thermal radiation, and make the boilers perform optimally and more energy efficiently, which in turn leads to lower CO2 emissions. Learn more about thermal insulation here >

Our PAROC® Pro Slabs (WR) and Wired Mats (WR) have been specially developed to meet these demands. Due to the high flexibility and mechanical strength of stone wool, they are perfectly suited for use at elevated temperatures. The excellent thermal properties of stone wool can withstand extremely high temperatures (up to 700 oC) and large temperature differences in different parts of the boiler.

Please consult the respective product data sheet for more information.