Flexible insulation solutions avoiding heat loss and thermal bridges

Flexible insulation solutions avoiding heat loss and thermal bridges

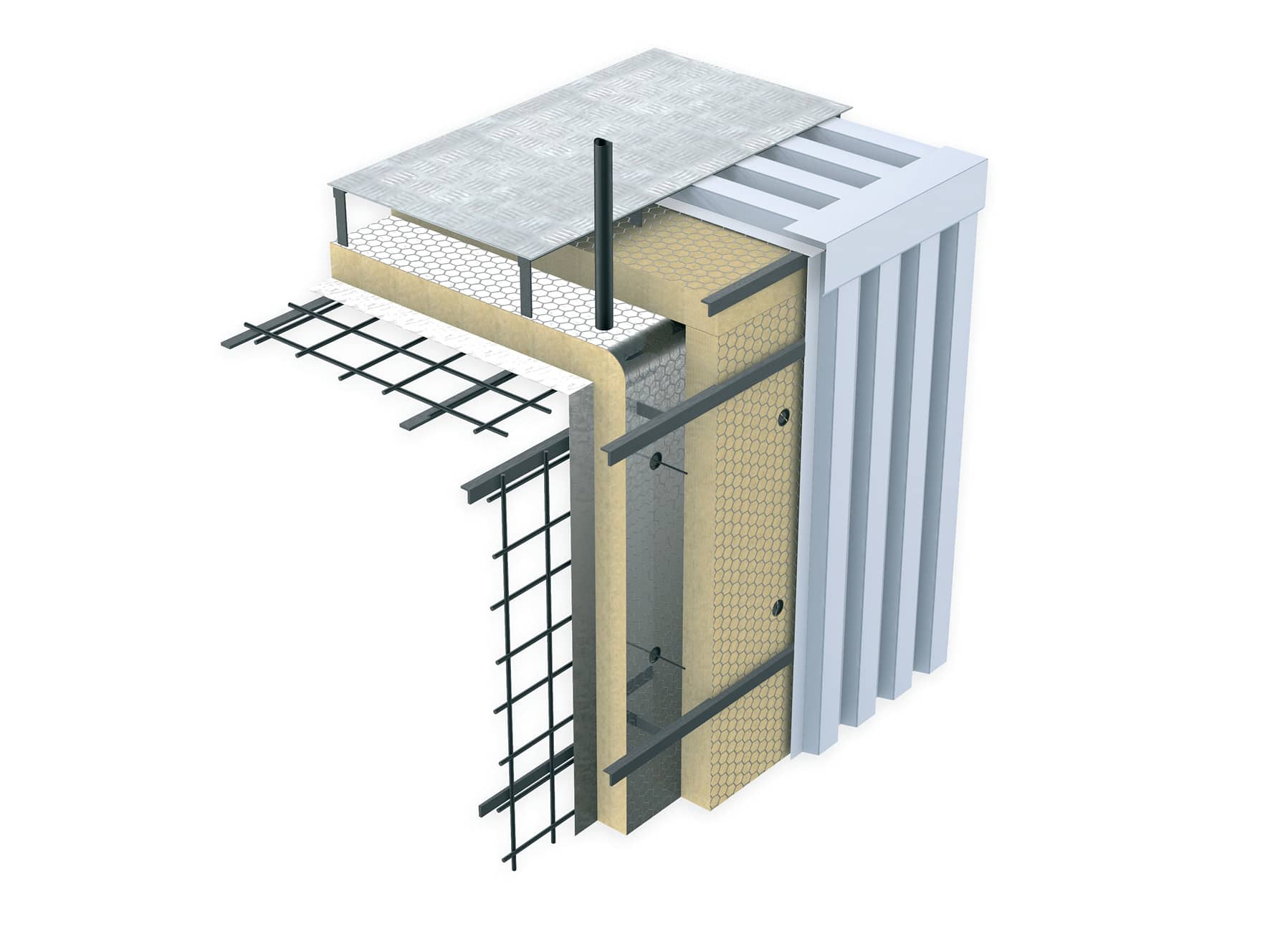

As boiler penthouses have pipe connections above the boilers, special insulating structures are required that can bear the weight of maintenance staff and plant operators. PAROC® offers insulation solutions for boiler penthouses that can help minimize thermal loss and thermal bridges and prevent the boiler room from overheating. Our stone wool insulation material has a high flexibility and mechanical strength, which supports optimum insulation even with large temperature fluctuations.

This is necessary because the insulation material for the boiler penthouse has to withstand the extremely high temperatures of the boiler, while the temperatures in other areas can fluctuate. In addition, the casing and pipes of boilers are often exposed to constant vibrations caused by connected devices such as burners and fans.

This allows you to control your boiler's process temperature, enabling it to work more efficiently and increasing its overall operation performance. Lower energy consumption also means lower CO2 emissions.

Please consult the respective product data sheet for more information.