The right solution from below

ambient temperature to 700 °C

The right solution from below

ambient temperature to 700 °C

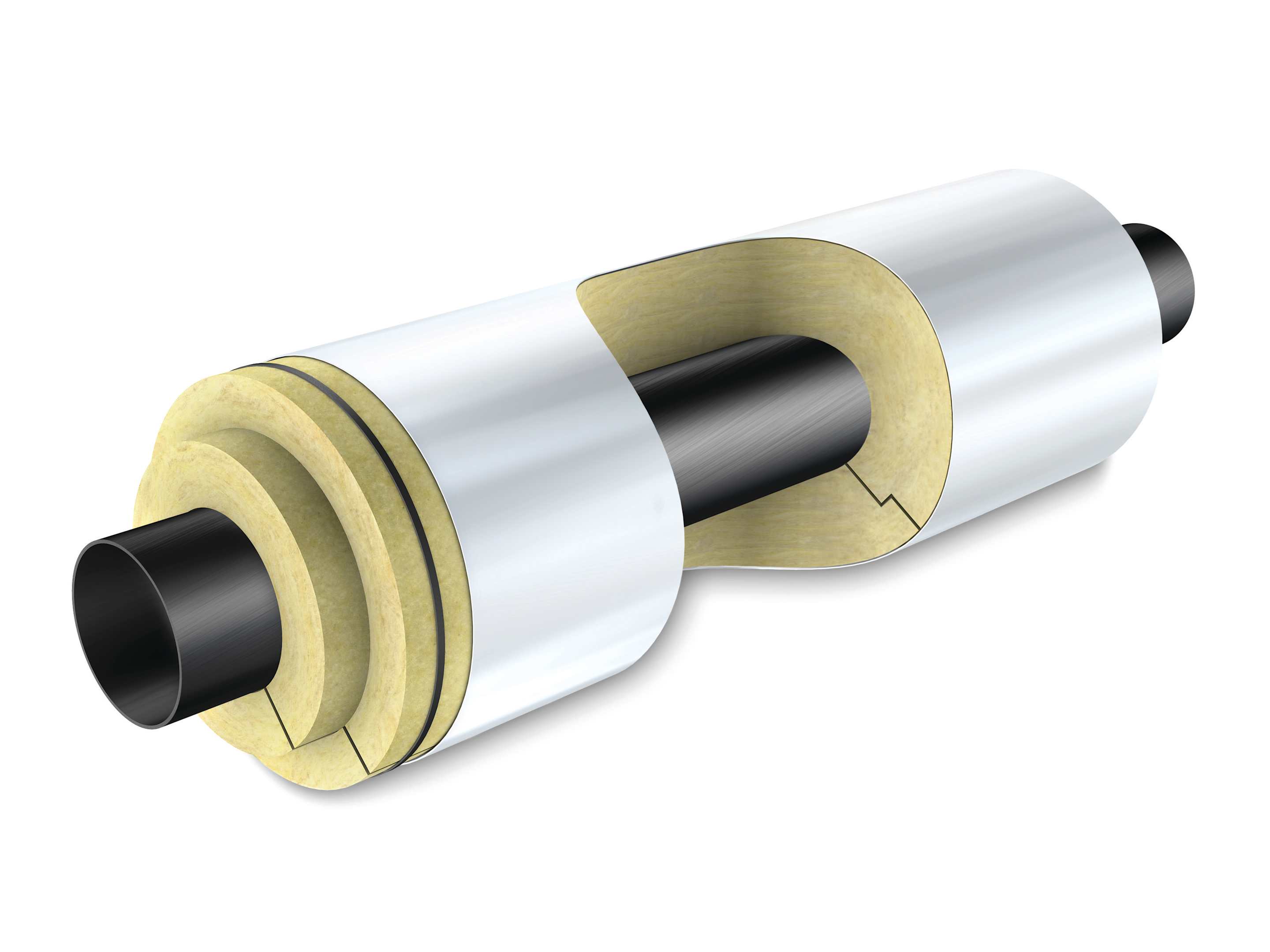

Choose your insulation solution based on the temperature at which the pipes operate and on other specific project requirements; our offering range includes both single and multi-layer solutions.

Our dimension guide and our package guide will support you in identifying the right pipe section and elbow solutions for your application.