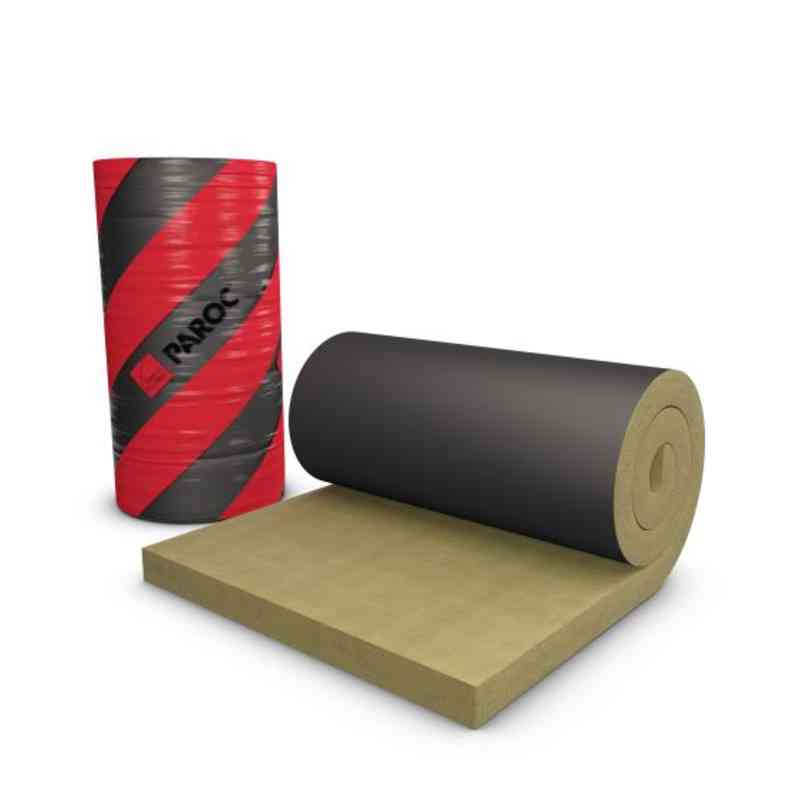

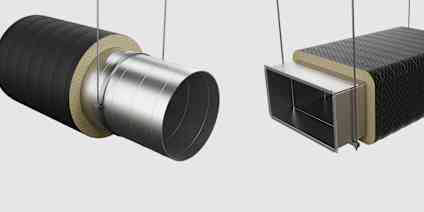

“The main challenge is to engineer products that are fully compliant and yet competitive in the market. Customers want solutions that are light and flexible, but to meet strict fire requirements, sometimes you need to make products thicker, denser, and less flexible than customers might prefer,” says Owens Corning R&D Leader Melanie Aubert.

“Our goal was to build a portfolio that is stronger and meets all criteria for fire safety. This challenge became an opportunity to fundamentally reimagine our approach to HVAC fire protection solutions. Instead of quick fixes, we embarked on a comprehensive re-development journey”, Aubert adds.