Safety Beyond Surface

Safety Beyond Surface

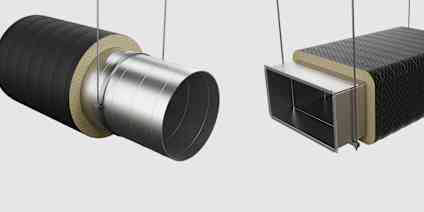

Behind the walls and beneath the wooden beam attic, critical details make this new space not just livable, but safe. The solution protecting the building's ventilation ducts is PAROC® Vect Mat BlackCoat EI60, designed as a one-layer installation with a 3-in-1 system that combines passive fire protection, condensation risk reduction and thermal insulation for circular ductwork in HVAC systems.