Reduce thermal loss for an optimal insulation

Reduce thermal loss for an optimal insulation

The purpose of industrial heat exchangers is to enable the exchange of thermal energy, that would otherwise be lost. For example, the energy recovered in the form of heat can be fed back into the production process. This allows enormous savings in the consumption of primary energy, a reduction in CO2 emissions and therefore savings in the costs of heating and production processes.

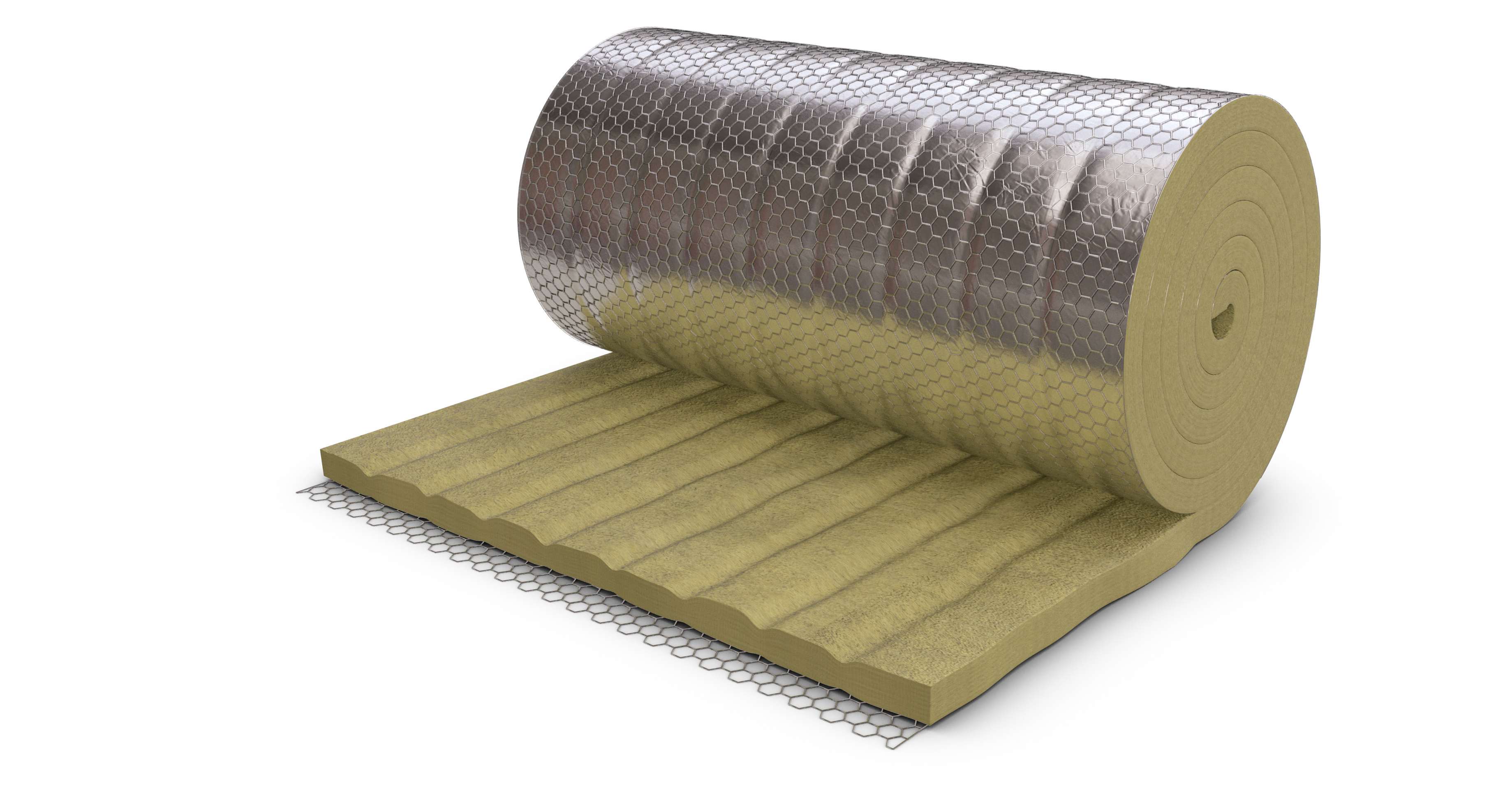

The construction of these process systems usually requires different insulation and cladding options depending on the size and operating temperatures. The proper insulation can be crucial to the optimum performance and longevity of the system and helps to maintain an effective process temperature.