The right insulation for flue ducts

The right insulation for flue ducts

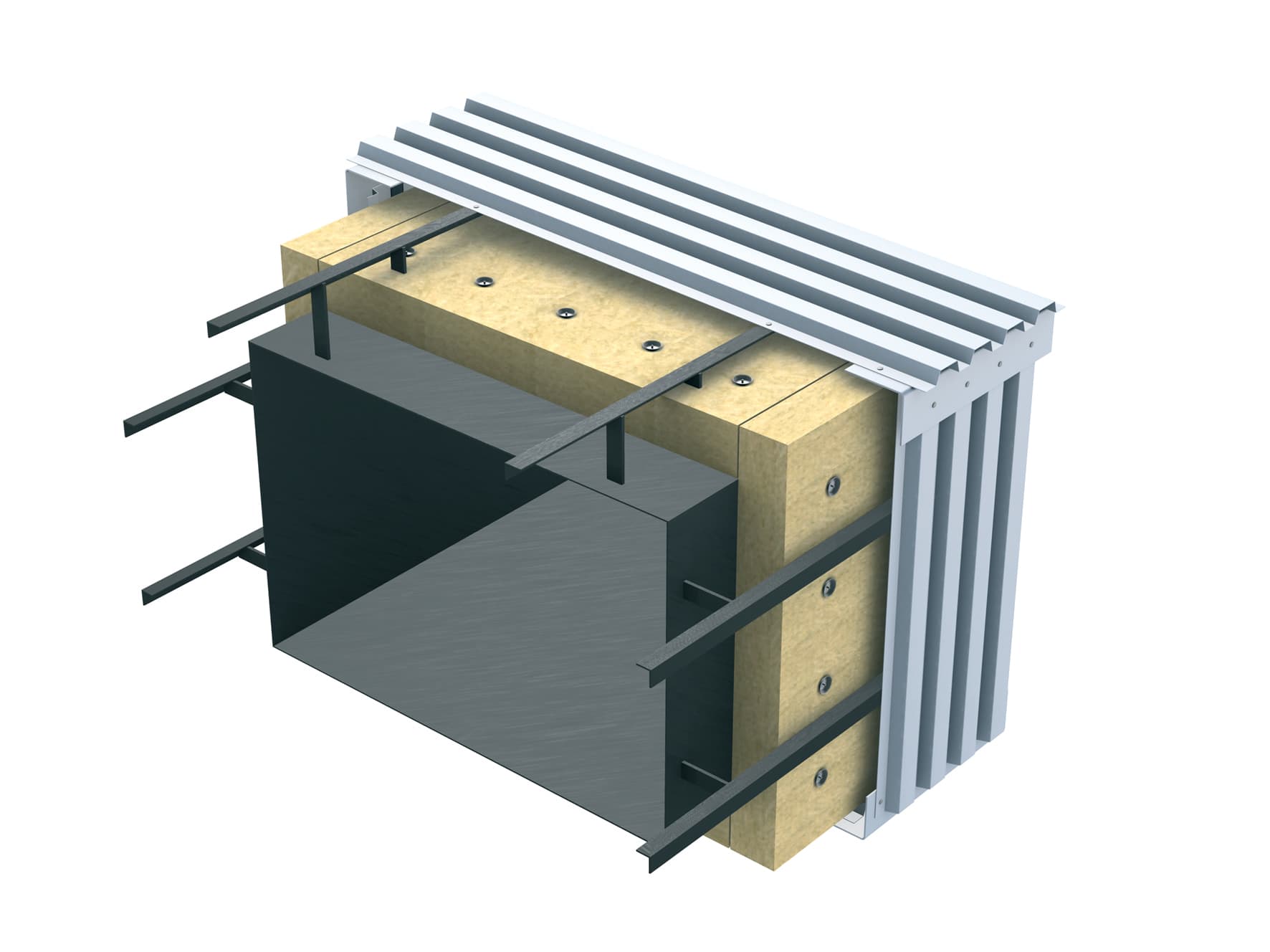

The transportation of large quantities of air or other gases is crucial in many industrial settings. This process is often characterized by high flow speeds, temperature changes, and pressure fluctuations within the flue duct systems. In addition to normal calculation parameters (temperature, size, length, orientation), the internal convection surface coefficient may affect thermal results.

Finding an optimal solution for each unique application can be challenging. It is important to consider characteristics such as resilience, longevity, energy efficiency, and mechanical strength.