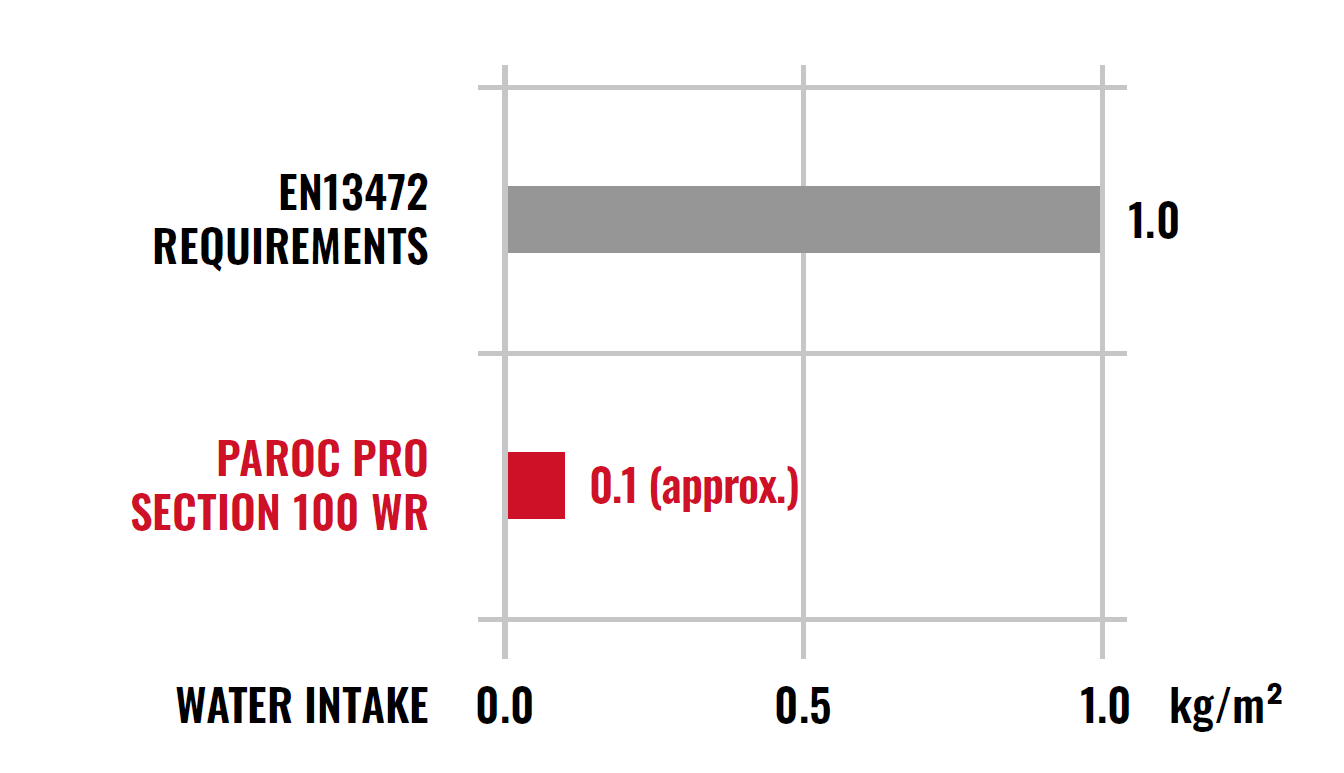

Low water absorption

Low water absorption

One of the biggest challenges in insulating industrial applications is the prevention of corrosion under insulation (CUI). The consequences of CUI can be costly as they can lead to additional inspections and higher operating and maintenance costs1. CUI can cause longer downtimes, a shorter service life for pipes, risk of leakages and systems and – in the worst case – even result in personal injury.