Reduce thermal loss and prevent CUI

Reduce thermal loss and prevent CUI

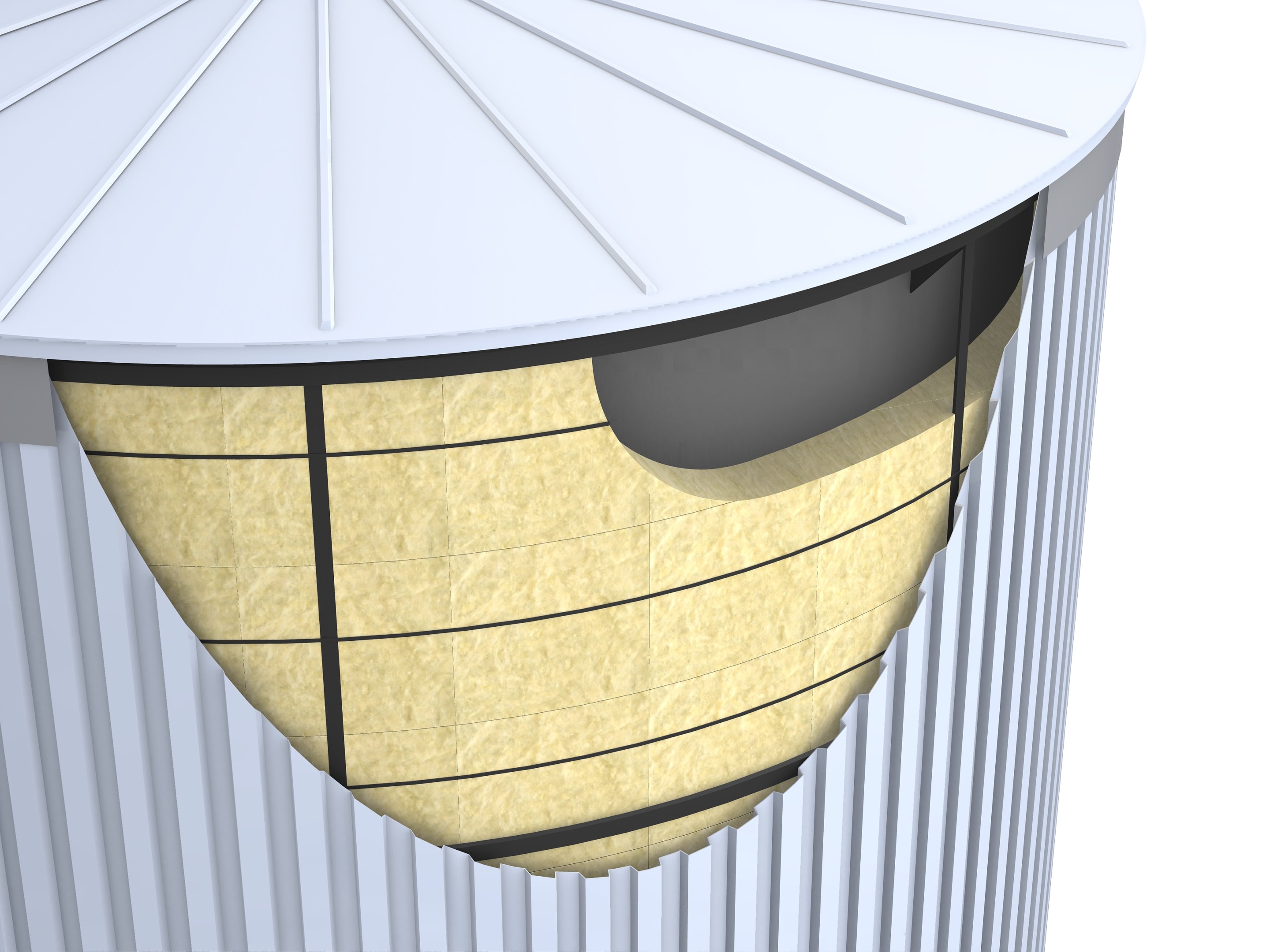

Storage tanks are usually an essential part of many industrial processes and come in various shapes and sizes. The temperature of the material stored in tanks can vary greatly from process to process. Proper and tight thermal insulation helps minimize thermal loss so that the contents of the tank are not exposed to temperature fluctuations. Learn more about thermal insulation >

Low lambda values and excellent water-repellent properties are the most important characteristics to consider when selecting insulation materials for moderate-temperature storage tank walls. Resilience as a combination of pressure resistance and flexibility is also a valuable property when insulating vertical walls.

All our products for the insulation of tank walls and tank roofs are available as WR (water-repellent) products. Since their average water absorption is 10 times lower than the toughest known standard (EN1607), they provide excellent protection to minimize the risk of CUI (corrosion under insulation).