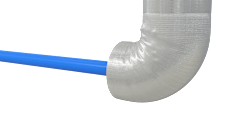

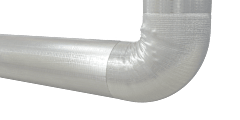

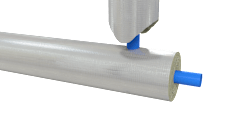

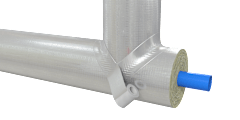

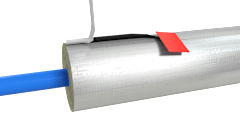

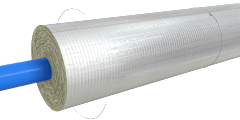

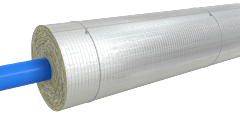

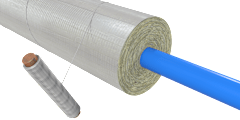

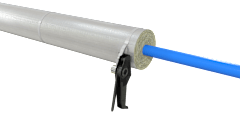

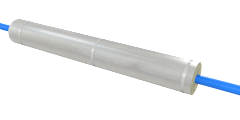

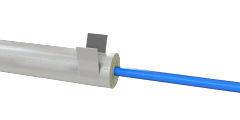

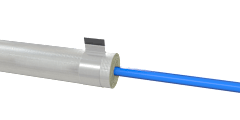

Installation instructionsParoc Hvac Section AluCoat T

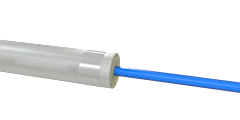

Paroc Hvac Section AluCoat T

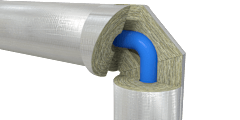

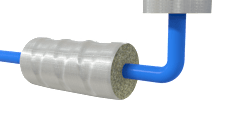

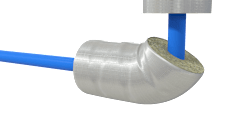

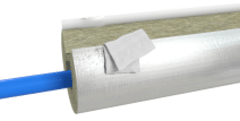

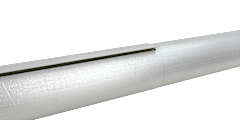

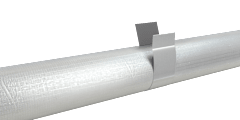

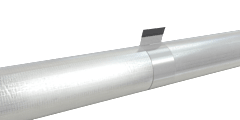

PAROC Hvac Section AluCoat T is a non-combustible stone wool pipe section for thermal and condensation insulation of pipework and air ducts in buildings and ships. It has a reinforced aluminium foil facing and tape in the longitudinal seam which prevents condensation and gives a quick installation.

2024-08-14